Warehouse Racking System Indonesia

Heavy Duty Rack Supplier, Manufacturer, & OEM/ODM

A warehouse racking system is the backbone of any modern warehouse operation. Whether you are managing fast-moving consumer goods, industrial raw materials, or palletised finished products, the right racking system directly affects storage capacity, picking efficiency, safety, and long-term operational costs.

EMTS Group provides complete warehouse racking system solutions in Indonesia, covering design, manufacturing, installation, inspection, and OEM/ODM custom fabrication. As a heavy duty rack supplier and manufacturer, we help businesses optimise warehouse space while meeting safety and operational requirements.

What Is a Warehouse Racking System?

A warehouse racking system is a structured storage system designed to store goods, typically palletised vertically and horizontally using steel frameworks. Its main purpose is to maximise warehouse space, organise inventory, and allow safe access using material handling equipment such as forklifts or reach trucks.

In practice, a well-designed racking system supports:

- Higher storage density

- Faster picking and put-away operations

- Improved inventory control

- Enhanced warehouse safety

In Indonesia, warehouse racking systems are widely used across logistics, manufacturing, retail distribution centres, cold storage, and industrial facilities.

Main Components of a Warehouse Racking System

Every racking system consists of several key structural and safety components:

- Upright Frames: Vertical load-bearing columns

- Beams: Horizontal supports that hold pallet loads

- Bracing: Structural reinforcement for stability

- Base Plates & Anchors: Secure the rack to the concrete floor

- Decking / Pallet Support Bars: Provide additional load support

- Rack Protectors & Barriers: Prevent forklift impact damage

- Load Rating Plates: Display maximum safe load capacity

Understanding these components is critical when specifying a heavy duty racking system, as each element affects strength, durability, and safety.

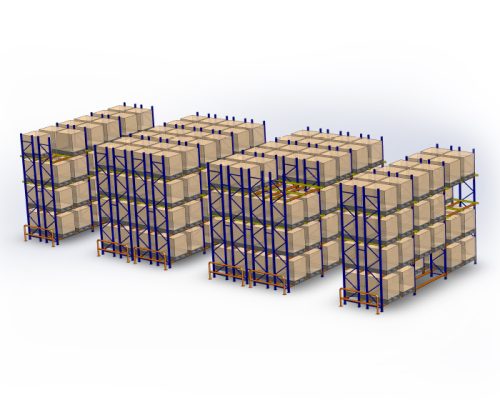

Types of Warehouse Racking System

Choosing the right racking system depends on inventory type, pallet size, SKU quantity, and warehouse workflow. Below are the most commonly used racking systems in Indonesia.

Selective Pallet Racking System

The most widely used warehouse racking system.

Best for:

- High SKU variety

- Direct access to every pallet

- FIFO or LIFO inventory management

Advantages:

- Cost-effective

- Easy to install and modify

- Compatible with most forklifts

Double Deep Racking System

An extension of selective racking where pallets are stored two-deep.

Best for:

- Medium SKU variety

- Higher storage density than selective racking

Trade-off:

- Reduced pallet accessibility

- Requires reach trucks or specialised forklifts

Drive-In / Drive-Through Racking System

High-density storage system where forklifts drive directly into rack lanes.

Best for:

- High-volume, low-SKU inventory

- LIFO (Drive-In) or FIFO (Drive-Through) operations

Common applications:

- Cold storage

- Food & beverage warehouses

Push Back Racking System

Pallets are stored on inclined rails and pushed back as new pallets are loaded.

Best for:

- Medium SKU variety

- High storage density with faster access than drive-in

Pallet Flow (Gravity Flow) Racking System

Uses gravity rollers to move pallets from loading to picking side.

Best for:

- FIFO inventory

- Expiry-sensitive products

- High throughput warehouses

Cantilever Racking System

Designed for long or irregular materials.

Best for:

- Steel pipes

- Timber

- Aluminium profiles

- Construction materials

Functions of a Warehouse Racking System

A warehouse racking system plays a critical role in daily warehouse operations by:

- Maximising storage capacity on the available floor area

- Supporting fast and accurate order picking

- Allowing goods to be moved safely using forklifts

- Controlling and displaying load capacity

- Organising goods by level, depth, and product range

These systems are widely used in logistics centres, manufacturing plants, cold storage, food and beverage, chemical, and distribution warehouses.

Heavy Duty Racking Systems

Heavy duty racking systems are engineered to support high load capacity, greater rack heights, and intensive daily use. These systems are suitable for industrial environments where large pallet loads are handled frequently.

Characteristics of Heavy Duty Racking

- High-strength beams and uprights

- Designed for heavy pallet loads

- Stable and safe structure

- Long service life

As a heavy duty rack manufacturer, EMTS Group designs and builds racking systems that meet operational and safety requirements.

How to Choose the Right Warehouse Racking System

Selecting the wrong racking system can lead to space inefficiency, safety risks, and costly modifications. Consider the following before making a decision:

- Pallet size and weight

- Number of SKUs

- FIFO or LIFO requirements

- Forklift type and aisle width

- Warehouse clear height

- Floor flatness and load capacity

- Future expansion plans

At EMTS Group, we start every project with a technical assessment to ensure the racking system matches your operation, not the other way around.

OEM / ODM Warehouse Racking Services

EMTS Group offers OEM and ODM services for warehouse racking systems, supporting distributors, contractors, and project owners.

OEM Services

- Manufacture based on your drawings and specifications

- Custom dimensions and load ratings

- Private labelling and branding

ODM Services

- Design + engineering by EMTS Group

- Custom racking solutions for specific applications

- Prototype bay and testing (if required)

What Can Be Customised?

Rack height, depth, and bay width

Load capacity

Colour and finish

Accessories and safety components

Packaging and project-specific requirements

EMTS Group Process: End-to-End Racking Solution

We provide a complete warehouse racking system solution in Indonesia, from concept to completion.

01

Site Survey & Requirement Analysis

- Warehouse measurement

- Inventory analysis

- Material handling equipment review

02

Layout Design & Engineering

- 2D and 3D racking layout

- Load calculations

- Space optimisation planning

03

Manufacturing & Quality Control

- Precision fabrication

- Powder-coated finishing

- Strict quality inspection

04

Installation & Commissioning

- Professional installation team

- Anchor testing and alignment checks

- Load rating signage and handover

05

Inspection & Maintenance

- Rack safety inspection

- Damage assessment

- Preventive maintenance planning

Applications Across Industries

Our warehouse racking systems are used in:

- Logistics and distribution centres

- Manufacturing warehouses

- Cold storage

- Food and beverage

- Chemical storage facilities

Why Choose EMTS Group?

Selecting the right partner for your warehouse racking system is critical to safety, efficiency, and long-term performance. EMTS Group provides engineered racking solutions that are designed for real warehouse operations.

Experienced Heavy Duty Rack Supplier

EMTS Group is a reliable heavy duty rack supplier supporting warehouses, distribution centres, and industrial facilities across Indonesia. We supply heavy duty racking systems designed to handle high load capacity, frequent forklift movement, and demanding operational environments.

Custom Design & OEM / ODM Capabilities

Every warehouse has unique requirements. We offer fully customised racking system solutions, including OEM and ODM services, covering dimensions, load ratings, finishes, accessories, and project-specific configurations. This ensures each system suits your space, products, and operational flow.

Focus on Safety & Performance

Safety is a core priority in every system we deliver. Our warehouse racking systems are designed with verified load calculations, proper anchoring, and essential safety accessories to protect employees, stored goods, and warehouse infrastructure.

End-to-End Technical Support

From initial site survey and system design to installation and after-sales support, EMTS Group provides complete technical assistance throughout the project lifecycle. This ensures your racking system operates safely, efficiently, and reliably over time.

Contact EMTS Group

If you are looking for a reliable warehouse racking system supplier in Indonesia, EMTS Group is ready to help. We offer companies build efficient, safe, and scalable storage systems. Contact us today!

Frequently Asked Questions (FAQ)

What is a warehouse racking system?

Can warehouse racking systems be customised?

Yes. EMTS Group provides fully customisable racking systems through OEM and ODM services.

Which racking system is best for heavy loads?

Heavy duty selective pallet racking or drive-in racking systems are commonly used for high-load applications, depending on access requirements.

What is the best warehouse racking system for many SKUs?

Selective pallet racking is often the best fit because it provides direct access to every pallet position and supports varied product range and fast picking.

How do I calculate load capacity for racks?

Capacity should be defined per pallet, per level, and per bay, based on upright frames, beams, connectors, and your handling method. EMTS Group sizes the system using your pallet weights, sizes, and operating conditions.

Do you provide installation and inspection services?

Yes. We offer installation, commissioning, inspection, and maintenance services as part of our complete solution.